|

|

08-05-2016, 01:35 PM

08-05-2016, 01:35 PM

|

#1

|

|

Platinum Member

Join Date: May 2014

Location: Greer, South Carolina

Posts: 2,611

|

Battery temperature sensor

Battery temperature sensor

The new victron monitor I ordered had an option for a temp sensor. I assume the intent is to adjust SOC based on degradation at cold temps.

That's fine I suppose for lead acids, but not necessarily tells you anything with lithiums.

I ordered it anyways because it was fairly cheap and I'd like a good idea of the battery temp just for monitoring purposes. I also ordered the bluetooth transmitter so I can get all the data on my iphone.

So the question I have is, how good a method is this to get an internal battery temp? The sensor is mounted on the positive post on the battery. I would think this would just be the same as the outside ambient temp. Or does it really work?

|

|

|

08-05-2016, 01:56 PM

08-05-2016, 01:56 PM

|

#2

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Quote:

Originally Posted by wincrasher

The new victron monitor I ordered had an option for a temp sensor. I assume the intent is to adjust SOC based on degradation at cold temps.

That's fine I suppose for lead acids, but not necessarily tells you anything with lithiums.

I ordered it anyways because it was fairly cheap and I'd like a good idea of the battery temp just for monitoring purposes. I also ordered the bluetooth transmitter so I can get all the data on my iphone.

So the question I have is, how good a method is this to get an internal battery temp? The sensor is mounted on the positive post on the battery. I would think this would just be the same as the outside ambient temp. Or does it really work?

|

I think the battery post mounted temp sensors are fairly imprecise. It is hard to imagine that they could accurately read the internal temp of the battery while hanging in the air. On our old system, we had one sensor that was on the post, and one that was on the battery case, and they matched fairly well at low speed temp changes, but got further different as the temp changed quickly or the air around the batteries got hot. It is probably time for me to take some IR heat gun readings and compare them to the sensors on our new setup. I have found the two sensors read a few degrees different even though they are on the same post.

On your lithium batteries, it is likely that you only have a wire to the battery post, so less heat transfer path than normal batteries, so you probably would be even less accurate. Using a temp gun to compare would be interesting, but even then the case isn't intimately in contact with the guts of the battery like in a wet cell or AGM.

I do find it interesting that folks like Magnum and some others don't use the standard temperature compensation factor that most of the battery manufacturers recommend. I think it is to try to compensate for the less than great battery temperature readings.

|

|

|

08-05-2016, 02:09 PM

08-05-2016, 02:09 PM

|

#3

|

|

Site Team

Join Date: Jul 2013

Posts: 5,339

|

There is a hefty solid metal path into the battery from the terminals. It conducts heat far better then does air. I am pretty sure that terminal-mounted temp sensors work just fine.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

08-05-2016, 02:16 PM

08-05-2016, 02:16 PM

|

#4

|

|

Platinum Member

Join Date: May 2014

Location: Greer, South Carolina

Posts: 2,611

|

As you might imagine, my concern would be for my lithiums getting down close to 32 F so I can take the necessary precautions on charging.

|

|

|

08-05-2016, 03:02 PM

08-05-2016, 03:02 PM

|

#5

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Quote:

Originally Posted by avanti

There is a hefty solid metal path into the battery from the terminals. It conducts heat far better then does air. I am pretty sure that terminal-mounted temp sensors work just fine.

|

I think the biggest problem is that you have a sensor that is hanging out in the air that can change temperature a whole lot, as well as the just the post cooling off, from ambient changes. It is also connects to, in many cases, a huge heat sink battery cable that will either be hotter or colder than the battery as it is charged or discharged, and that cable will conduct heat just as well as the battery post to internals connection.

Pretty simple to test with the IR temp gun. Shoot the post/sensor, the battery case a couple of places, and the battery cable. In our case I would expect the cable to be adding heat to the sensor when the engine is running, as it is closer to the exhaust.

I think it would be interesting to move one of our sensors to the case, taping or tie wrapping it on so good contact, and then some insulation over the sensor.

|

|

|

08-05-2016, 03:29 PM

08-05-2016, 03:29 PM

|

#6

|

|

Site Team

Join Date: Jul 2013

Posts: 5,339

|

Quote:

Originally Posted by booster

I think the biggest problem is that you have a sensor that is hanging out in the air that can change temperature a whole lot, as well as the just the post cooling off, from ambient changes. It is also connects to, in many cases, a huge heat sink battery cable that will either be hotter or colder than the battery as it is charged or discharged, and that cable will conduct heat just as well as the battery post to internals connection.

Pretty simple to test with the IR temp gun. Shoot the post/sensor, the battery case a couple of places, and the battery cable. In our case I would expect the cable to be adding heat to the sensor when the engine is running, as it is closer to the exhaust.

I think it would be interesting to move one of our sensors to the case, taping or tie wrapping it on so good contact, and then some insulation over the sensor.

|

Your thermodynamic intuitions are very different from mine. In this kind of analysis, the thermal conductivity of the various materials makes all the difference. Metal conducts heat far, far better than either air or plastic. The ambient air is going to make a much smaller contribution to the sensed temperature than the metal terminal, which leads directly into the heart of the battery. The plastic case wouldn't be great, either. There is a reason the nurse sticks the thermometer into an bodily orifice rather than on your skin. The terminals are the closest we have to a bodily orifice in this case.

You DO have a point about the large battery cables, but they are insulated and so are likely to serve more as a ballast than as a bias (i.e., they will tend to slow down the temperature changes at the terminal). Also, this is one of many reasons to use MRBF fuses right on the battery terminal. They act as a thermal insulator, at least to some extent:

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

08-05-2016, 04:00 PM

08-05-2016, 04:00 PM

|

#7

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Quote:

Originally Posted by avanti

Your thermodynamic intuitions are very different from mine.

|

I agree, and that is why some testing is needed to see what is real, or not. I wish I had a thermal camera, as they show everything at once.

Three main ways to move heat. Conduction, convection, radiation.

The battery guts to post is pure conduction and is temp diff, distance, and coefficient dependent.

At the post you have some of everything. Conduction to get the heat to the surface, conduction of the heat to the cable, conduction at the air interface, convection to carry the heat away with moving air, and radiation off the surfaces. The air moving is the critical part because it maximizes the temp difference between the surface of the post and sensor and the air. Insulating the post and sensor would certainly help this.

The cable will get or give heat to the post and sensor with by conduction, and it's materials will transfer that heat very quickly, just like the heat coming from or to the battery guts. The cable will also heat up by conduction and convection from the surrounding air temp, but a bit slower because of the insulation. There is so much heat transfer area in the cable, though, so still could be a big factor. It could also heat, or cool, by radiation from it's, or other, surfaces like hot asphalt, exhaust pipes, etc.

All this is pretty readily modeled with right software, but requires a lot of work and expertise. On non-critical stuff like this, it is common to build a prototype and just look at it with a thermal video camera over a period of use. We used to do that all the time with control panels, motors, ovens, etc, before we would put them into use on our capital equipment projects. On the consumer stuff we made, that was all done by UL and CSA in the approval process, so we didn't have to be as accurate initially. They have super accurate testing available.

My guess is that the cable could turn out to be the biggest factor.

|

|

|

08-05-2016, 04:10 PM

08-05-2016, 04:10 PM

|

#8

|

|

Site Team

Join Date: Jul 2013

Posts: 5,339

|

Totally agree about the need for data.

One question, though: How do you determine the "correct" temperature? What really matters is the "core" temperature of the battery, which is itself a heat source. Not obvious to me how you measure that. I guess you can make inferences from the deltas. But that would get complicated.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

08-05-2016, 04:47 PM

08-05-2016, 04:47 PM

|

#9

|

|

Platinum Member

Join Date: May 2014

Location: Greer, South Carolina

Posts: 2,611

|

Well the thing about lithium batteries is that their heat generation is practically nil. At least these prismatic type cells in the drop-in type cases.

The lipos generate alot more heat from my experience.

What I wonder is that translates into taking a long time to get cold, unlike metal plates which get cold quickly.

|

|

|

08-05-2016, 05:26 PM

08-05-2016, 05:26 PM

|

#10

|

|

Platinum Member

Join Date: May 2014

Location: Greer, South Carolina

Posts: 2,611

|

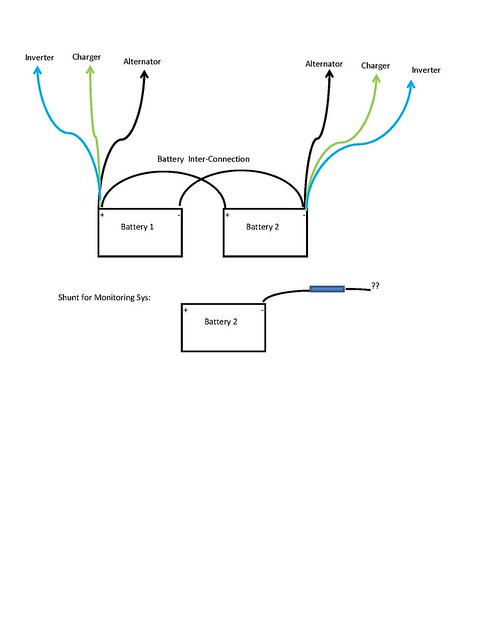

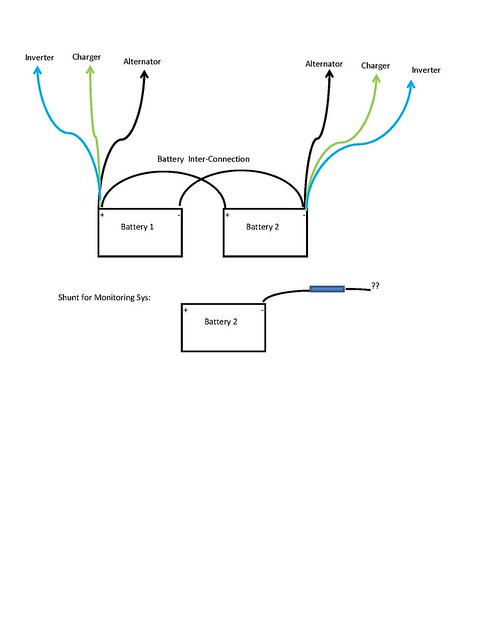

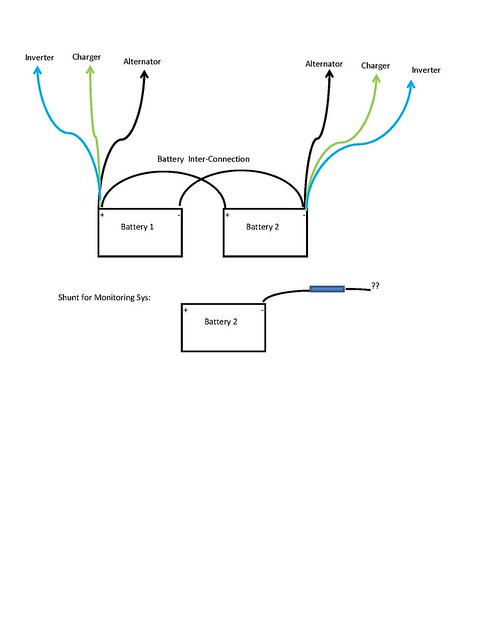

While I have your attention, here is a pic of my wiring setup. Unsure of the best placement to install the shunt for the Victron. Does it matter if it's on the cabling to the inverter? or the Charger? Would it be better if it was on the neg cable connecting the batteries to each other?

Also, I'm thinking it's wise to upgrade the wiring between the batteries to match the 4/0 cable I'm using for the inverter. Correct?

|

|

|

08-05-2016, 05:31 PM

08-05-2016, 05:31 PM

|

#11

|

|

Site Team

Join Date: Jul 2013

Posts: 5,339

|

Quote:

Originally Posted by wincrasher

While I have your attention, here is a pic of my wiring setup. Unsure of the best placement to install the shunt for the Victron. Does it matter if it's on the cabling to the inverter? or the Charger? Would it be better if it was on the neg cable connecting the batteries to each other?

Also, I'm thinking it's wise to upgrade the wiring between the batteries to match the 4/0 cable I'm using for the inverter. Correct?

|

The shunt MUST be at the negative terminal of battery #2. ALL current must pass through it with the exception of the ground wire that goes to battery #1.

The current between the two batteries is only half that of the current that goes to the load. The battery interconnect wires don't have to be as big as the load wires.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

08-05-2016, 06:03 PM

08-05-2016, 06:03 PM

|

#12

|

|

Platinum Member

Join Date: Jul 2012

Posts: 2,380

|

I would think the only way to get accurate cell temperatures would be with temperature sensors at the cells as is done on systems like the Elite Power cell balancer boards where they also collect individual cell voltages. All this then gets reported on the optional display via the BMS module that connects to all the cell balancing boards. ARV likely adds the CAN interface to the BMS to get the data to the Silverleaf system.

|

|

|

08-05-2016, 06:43 PM

08-05-2016, 06:43 PM

|

#13

|

|

Platinum Member

Join Date: Jul 2012

Posts: 2,380

|

Quote:

Originally Posted by wincrasher

While I have your attention, here is a pic of my wiring setup. Unsure of the best placement to install the shunt for the Victron. Does it matter if it's on the cabling to the inverter? or the Charger? Would it be better if it was on the neg cable connecting the batteries to each other?

Also, I'm thinking it's wise to upgrade the wiring between the batteries to match the 4/0 cable I'm using for the inverter. Correct?

|

Are the negative connections to those devices connected directly to the battery bank or are some simply connected to ground? There must also be a ground connection to the negative side of the batteries.

|

|

|

08-05-2016, 07:07 PM

08-05-2016, 07:07 PM

|

#14

|

|

Platinum Member

Join Date: May 2014

Location: Greer, South Carolina

Posts: 2,611

|

There are ground connections, but I'm not recollecting if there is one on the batteries. The charger has it's own ground, as will the inverter.

All the cabling is on the battery posts. I'm looking for suitable terminal bus bars to reduce the strain on the posts.

At some point, I believe the cables to the charger split and feed the 12 volt panel. I haven't found where yet, as it's somewhat of a rat's nest of wiring in that compartment under the bed. What makes me think this is that the wiring at the batteries is larger diameter than the 6 awg that is at the existing converter/charger.

|

|

|

08-05-2016, 07:21 PM

08-05-2016, 07:21 PM

|

#15

|

|

Platinum Member

Join Date: Jul 2012

Posts: 2,380

|

Quote:

Originally Posted by wincrasher

There are ground connections, but I'm not recollecting if there is one on the batteries. The charger has it's own ground, as will the inverter.

All the cabling is on the battery posts. I'm looking for suitable terminal bus bars to reduce the strain on the posts.

At some point, I believe the cables to the charger split and feed the 12 volt panel. I haven't found where yet, as it's somewhat of a rat's nest of wiring in that compartment under the bed. What makes me think this is that the wiring at the batteries is larger diameter than the 6 awg that is at the existing converter/charger.

|

I would think the thickest cable from the negative side of the batteries goes directly to a ground point. In any case, the only connection to the negative side of the batteries has to be directly to one side of the shunt.

|

|

|

08-05-2016, 07:24 PM

08-05-2016, 07:24 PM

|

#16

|

|

Site Team

Join Date: Jul 2013

Posts: 5,339

|

Quote:

Originally Posted by gregmchugh

In any case, the only connection to the negative side of the batteries has to be directly to one side of the shunt.

|

Yes. As long as by "batteries" you mean the whole ensemble. The cable interconnecting the batteries stays on the battery side of the shunt.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

08-05-2016, 07:28 PM

08-05-2016, 07:28 PM

|

#17

|

|

Platinum Member

Join Date: May 2014

Location: Greer, South Carolina

Posts: 2,611

|

Does it not matter which cable the shunt is attached to (alternator, charger or inverter)? From the instructions, one of these must be removed from the battery post and connected to the far end of the shunt. As small length of cable connects the shunt to neg terminal on the battery.

My first instinct is to go with the charger cable, as that system ends up connected to the 12v service panel at some point.

But will it still read my draws when the inverter kicks on?

|

|

|

08-05-2016, 07:39 PM

08-05-2016, 07:39 PM

|

#19

|

|

Platinum Member

Join Date: May 2014

Location: Greer, South Carolina

Posts: 2,611

|

Very nice!

|

|

|

08-05-2016, 07:43 PM

08-05-2016, 07:43 PM

|

#20

|

|

Site Team

Join Date: Jul 2013

Posts: 5,339

|

Quote:

Originally Posted by wincrasher

Does it not matter which cable the shunt is attached to (alternator, charger or inverter)? From the instructions, one of these must be removed from the battery post and connected to the far end of the shunt. As small length of cable connects the shunt to neg terminal on the battery.

|

ALL THREE cables must be removed from the negative battery post and moved to the far end of the shunt. That way, the shunt will "see" all current.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|