|

|

09-14-2010, 10:56 PM

09-14-2010, 10:56 PM

|

#1

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Photog's Lifted Suspension 2009 Roadtrek 190V

Photog's Lifted Suspension 2009 Roadtrek 190V

Introduction and modification summary:

This thread will follow our quest to increase the ground clearance of our 2009 Roadtrek 190 Versatile. The goal is to increase ground clearance by 4" to 6". We want to use our R/T to travel the back roads (sometimes dirt), to enjoy the secluded areas of North America, and do our best to create pleasing photographic art.

Since there is no aftermarket support for these Chevrolet vans, this suspension modification will be something of an adventure. I will try to keep this first post updated, as to our current suspension system. Read all the pages of this thread, to follow along in the adventure. Other folks will add their modification ideas, pictures and experiences. I believe we will all learn something useful, by the time this adventure is complete.

Situation:

Well, we have had our Roadtrek 190V for since Sept 2009.

I must say that this thing is very low to the ground, and the long wheelbase makes for at lot of belly dragging. The problem is, the low point is the black/gray water valve. It was damaged while it was still on the sale-lot (fixed by the dealer), and I had to take the valve apart and re-assemble it once, because I drug-bottom.

My solution was similar to these: http://cstsuspension.com/chevy-perorman ... ndles.html

These are 4" lift spindles for the front suspension. Very well made equipment.

The rear currently has 4" lift blocks, but will have a custom set of springs.

One issue with the 2008 Chevy 3500 Express: the rear brake hoses are not long enough, even for the factory setup. If you jack up the rear and support it under the frame, allowing the axle to hang freely, the brake hoses will be stretched very tight.

Since I added 4 more inches, I had the brake hoses lengthened an extra 7 inches, by a shop that builds brake lines for log trucks. These new lines are stout. That is 4" for the lift, and 3" because the factory was short to begin with.

Installing this lift is a serious job. I did it my self, but any good 4X4 shop could do it too. Check to see if they can deal with the weight of your RV.

Now I need to take it in for an alignment.

Here is the 'before' image: Notice where the lower edge of the body is, relative to the centerline of the axle. It is about level with the bottom of the wheel (top of tire sidewall).

Here is an 'after' image: The lower edge of the body is now just below the centerline of the axle.

I have not had a chance to get a nice side view, but I will replace this one, when I do.

Suspension #2:

For a number of reasons, the lift spindles/knuckles did not work out. They will need to be modified, to match the geometry of the factory knuckles. So the knuckles came out, and a set of Otto-Max TTC-1617 coils went in. These coils are a little stiffer than the factory springs for the Diesel powered van. They provide 2" of lift, and a smoother ride. The ride is smoother, because it gets the front suspension off of the overload/bump-stop, helping the suspension follow the larger contours & dips in the highway. But the stiffer spring makes for a rough ride on dirt roads. Here is a link to their website. http://www.otto-max.com/super-heavy-duty-coils.html

Here is what it looks like, with the new coils in the front, and 4" lift blocks in the rear.

Suspension #3

New 3" knuckles in the front, from Boulder Offroad, in Colorado. These knuckles are designed for the van. Perfect geometry that was easy to align properly. Rear still has 4" blocks.

Here is a link: http://boulderoffroadvans.com/gm__chevy ... _lift_kits

and a photo of the parts (right click on the photo, and select "view image")

We also upgraded to an 18" wheel, and tires, to increase the load capacity of the tires well above the weight of the Class B. This new wheel has a +18mm offset. this is much closer tothe factory offset than the AR-23 wheels that come with the Roadtrek. They have an offset of -6mm. THis means the centerline of our tires have moved 24mm (1") inboard. This reduces the wear on the bearings, and improves the steering geometry and handeling.

These are the wheels we purchased: 18x8.5 - +18mm.

http://www.visionwheel.com/wheel.cfm?id=729

Sept 2012 - Current stature of our R/T 190. The front is about 1" taller than the rear. This will be corrected, when I have the rear springs replaced.

Sept 2012: Otto-Max TTC-1617 front springs, Boulder Offroad 3" front knuckles, Bilstein Shocks all around, 4" blocks under factory rear leaf springs, extended rear brake lines, added rear sway bar.

Each of these modifications is discussed in detail, in the posts and pages that follow.

Cheers

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-14-2010, 11:38 PM

09-14-2010, 11:38 PM

|

#2

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Lifted Roadtrek

Re: Lifted Roadtrek

Wow, a 4" lift is a lot for an already top heavy beast, I would think. I couldn't find any load specs on the site for the spindle drops. Are they rated for the 4300# front axle weight of a Roadtrek?

We agree that the clearance on these things is horrible, we bottomed out our 07 C190P in Custer this year and busted up a black water valve.

I had been searching for a good way to lift it since we got it, and the parts I wanted finally came available. New front springs gave us 2" in the front, and airbags in the back gave 1.5". The back was already 1" above the front.

A big issue on the Chevy Roadtrek front is that they ride right down on the bumpstomps, so the rebound characteristics are terrible and uneven side to side. If you measure the suspension height per the factory manual, they sit over an inch lower than the lowest spec for any of the Express vans, putting the geometry out of whack. The 2" lift puts you right at the spec for the 3500 van. Using the lift spindle won't address that problem, and hitting the bumpstops will put an even larger load on the spindle parts. Getting off the bumpstops greatly improves the ride and driving characteristics of the van. We noticed a very big reduction in bumpsteer when we got it up in height.

In the rear, if you can get up off of the "overlaod" leaf, either with bags or higher rate springs, you will also get a marked improvement in ride quality. The overload leaf is so stiff, it is almost like having no spring at all, so small bumps seem big.

I would certainly think you would need longer shocks on both ends for 4" of lift, or extenders. The shocks on ours would stop the axle before the brake line was too tight.

Using lift blocks in the rear, or big arch springs, usually makes the rear more prone to side sway, as the spring connection to the axle is a bunch further away from the spring eye/shackle line, increasing the leverage on spring twist. Have you seen any issues with this? At some point a track arm would possibly be needed.

There has been a lot of chatter and discussion of how to lift the Chevies (Roadtrek and Pleasureway) on several boards and forums. This is the first I have seen of the lift spindles, so it will be interesting to hear how it all works out for you. I know many folks will be interested. I know folks have had trouble with the 2" urethane spring spacers, as they split from the heavy front end weight. Daystar now only recommends them for light duty trucks.

Here is a link to another board on how ours turned out. We now have 8" clearance at the blackwater valve, and it actually handles better than before.

http://www.rv.net/forum/index.cfm/fu...3.cfm#24289693

|

|

|

09-15-2010, 06:35 PM

09-15-2010, 06:35 PM

|

#3

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

I agree with you, on the suspension acting poorly, being mashed down like it is. With the drop spindle, the suspension still sits very close to the bump stops. The rear springs are almost flat, with the van's weight resting on it. That means the springs move from positive to negative arch, during normal use. That is not a good thing, for leaf springs. When we get the new rear springs made, there will be no need for the 4" lift block, and the springs will appear to have a normal arch, with the van's weight resting on them.

I think a new set of front springs and a different bump stop (Timbren http://www.timbren.com/timbren-appli...fs/GMFK15A.pdf) would be a big help. Maybe I will do that, before ordering the rear springs, so I can get the ride-height level. I read through the link you posted. Great info.

I have a request for information to CST, about their spindles. If they will live under the load, and I add another 2", to get the geometry back in order, then the total lift will be 6". That sounds like a lot, but not if you consider the R/T already sits 2" lower than stock ride height.

I don't feel like our van is top-heavy. Most of the weight is down low, unless I fill the upper cabinets with canned food & water (we don't  )

As for the shocks needing to be longer: The rear does need to be longer, since the axle is further from the frame. The front does not change. Only the center of the spindle moves down, not the lower A-Arm (Lower Control Arm).

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-15-2010, 09:26 PM

09-15-2010, 09:26 PM

|

#4

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

It will be very interesting to see what CST says about the application. The website is a bit confusing. The spindles are in the 1500/2500/3500 section, but only state that they are for the ones that are smaller than the 3500. I think everything they listed was 3/4 ton or lighter and would have about 1000# less gross weight capacity.

I have always been a bit scared about drop and lift spindles, as (obviously) they move the spindle position in relation to the ball joints and other suspension parts, which can change the way the vehicle reacts under certain circumstances. How good or bad it gets is oftentimes related to how well the factory had the original setup designed. Most of the time on lift spindles it takes the spindle from between the balljoints to below them both, which changes the loads they see, and the direction they see them in some cases. Accelerated balljoint wear is very common, especially on the lowers. Braking forces also significantly redirected, and on a 9600# vehicle are very large. Moving them to a lever arm under the lower balljoint is a big loading shift. Of course, all bumps and side (cornering) loads work through the longer lever arms also. This is a bit of an odd application, I think, as the trucks I see lifted much are usually not heavy haulers, but high clearance offroaders, run empty.

I think that your plan of getting new front springs is good from several angles. As was mentioned before, getting the suspension to the correct height makes the geometry work better, and getting it off the bumps will give more linear compression and jounce responses. The link you put up for the different bump stops is interesting, but they may not be as much different as is first assumed. In the GM truck suspensions, like that in the Express, the bump stops are an active part of the spring system for the front. They are intended to work very much the same as the "overload" leaf in the rear, and to come into play on large bumps or heavy loads. They are not like the old wedge shaped rubber bumps of old, that were there to stop overtravel only. The bumps appear to be urethane, in the shape of a beehive, with a hollow core. As they are compressed, they go into a tube to constrain them from overbulging. To this extent, they work just like the ones described in the link, although the spring rate, preload, etc may be different. I think you will find that going to higher rate coil springs, and staying off the bumps, will give a better ride and also give much more consistent bump and dip response from the front end. Our springs went from being 4300# rated to 5000# rated, and the ride got smoother over big bumps, not rougher.

Rear spring design and geometry is one of those things that you will find 20 people with 20 different opinions. Here is my 1 of 20!

I have found high arch springs to almost always result in worse handling and control. I like to to see a leaf spring with a bit of arch under normal load, and almost flat when compressed to near its max capacity. This minimizes that bending (twist) moment the spring sees in corning side loads and also helps with the linearity of the spring rate, as it is less effected by the radius the load is applied to. If I were starting from scratch with a Roadtrek, I would have springs made that did not include the big, flat, "overload" leaf, as the van is nearly always loaded fully. OEM, the van has to ride OK with nothing in it, or 4000# in it, so they need that setup, but we only have to contend with about 1500# variations. If you get the spring made to carry the loads that it will see, it can be designed without that huge transition to the big leaf, and the spring rate will be much more linear and without abrupt changes. You will notice a much lower tendency to "buck" from the back as it comes off the overload leaf. By having lower arch to near flat over the travel of the spring, you minimize the amount of travel the rear shackle has to take up. This is a good thing because as the angle the shackle is at, at any given moment, determines how much extra resistance it is adding to the spring being compressed, and you are way better to let the spring do the resistance than the shackle. The position of the shackle, angle wise, is also very critical, for the best results. What I like to see would be to take an arbitrary straight line, from the spring where it attaches to the axle, through the shackle eye on the spring, and extended a bit. This is basically a chord on the radius of the arch of the spring. In the ideal, as the suspension goes through its travel, the shackle eye would start and end on that line. I haven't done this check on our Chevy, so I don't know how much shackle movement there is, but on cars we were usually able to get the travel very close to that line, and it would almost always have travel from about the 6:30 position to a maximum of 8:00 if there was a lot of travel. The springs will run very smoothly there, with very little kick, bounce, or bind.

Most of the stuff I have messed with entailed lowering the rear for better handling, but there were occasions where raising was necessary for tire clearance in the back. As I said earlier, I am not a fan of high arches or blocks. What we would do was not all that difficult, and did a very good job of maintaining good spring geometry. If the vehicle had a bolt on front spring eye, we would make a new one that was as much longer as we wanted to go up. If if was welded in, we could make an adapter or weld in a new one to do the same thing. In the back, we would make a new mount for the shackle, which was usually pretty easy. Most of the frames, or subs, were flat in that area, so all you needed to do was make a box of the amount you wanted to raise up, drill a hole through it for the shackle, and weld it in, under the existing place. By doing the lift this way, you only move the body away from the suspension, without affecting any of the suspension's functionality.

It is interesting that you don't notice a top heavy feeling. It may be because of what was driven before. I have always been in smaller cars, so the the Roadtrek seems huge and top heavy to me. I do notice a difference if I have all the tanks full, as I did when I took it to be aligned, as it feels more stable in winds. Our raising the back 1" and front 2" didn't really change the way it feels from the top heavy viewpoint, but it is probably due to the increased spring rates and better shocks. Getting the geometry right, and more predictable jounce, made it react to the steering input much quicker and more consistently. Most of the time, if you do much height increase, you need to increase the spring rates to compensate.

I have never seen an info on it, but the Roadtrek must have a pretty high center of pressure, as you can feel them lean in the wind, not just move over. We have found that the reaction to the wind in tracking and ease of steering it back where it belongs, got significantly better with changes we made (including the Bilsteins).

Keep us up to date on what you find out, what you decide to do, and how well it works out for you. Road clearance is an ongoing issue for most RT owners, so having as many options as possible will be a very good thing.

|

|

|

09-15-2010, 10:33 PM

09-15-2010, 10:33 PM

|

#5

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

This is a great conversation.

I have a big interest in vehicle suspension design. When I was still in college (BS Mechanical Engineer), I wrote a couple programs to provide optimum spring and damper specifications, based on vehicle weight, speed and terrain. My interests were geared toward high speed off road racing (think Trophy Truck class). Long before the custom spindle designs used today, I was designing knuckles with the spindle at the lower ball joint (or spherical bearing). Today, this is the standard design for serious racing in the desert.

In the case of this CST knuckle, the spindle (center of the hub sub-assembly) is just above the lower ball joint. It is definitely not below the lower ball joint.

.jpg)

I contacted CST, about the weight of the R/T front (4300# max). They said that was not a problem. They also said this knuckle is used on many of the 1ton (3500HD) trucks, while being thoroughly abused off road. The design and workmanship look to be much stronger than the factory casting. The factory casting does not show any evidence of being forged in any manner. We tend to travel the back roads (dirt, washboard, etc.). We will see how it all holds up.

As for the leaf springs: I am with you all the way. The factory springs are currently flat, with the RV weight on them. I would like them to have the normal arch with this load, and become closer to flat when in the max-load condition of 9,600#. For the rear axle, that could be as little as 5,300# (9,600# - 4,300#). There are factory spring packs for this van that carry the GVW even higher (close to 11,000# I believe). With the standard weight of our R/T's, I think that a set of the higher rate springs might be a better choice (like the diesel front springs you have).

Side note: The rear shackle hanger is inverted type (upside down). The shackle swings over the top of the hanger.

Like this---

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-15-2010, 10:45 PM

09-15-2010, 10:45 PM

|

#6

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

Interesting stuff. Having the spindle between the joints is a good thing. Did CST say anything, or do the spindles themselves, address the change in scrub radius you get by increasing the the distance from the ground to the ball joints? I see they had a max backpspacing listed and some suggested wheel and tire combos. I assume on a desert racer, you need all the clearance you can get, so the low spindle is a necessity. The good part would be the suspension would also be custom, so you could position the balljoints to wherever you wanted them to control the scrub, and caster.

I hadn't even looked at the shackles on ours to see they were inverted. It makes sense though, as the axle is under the spring. Most of the stuff we messed with had the spring under the axle.

|

|

|

09-15-2010, 11:19 PM

09-15-2010, 11:19 PM

|

#7

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

The knuckle definitely has the geometry modified from the stock equipment.

The end of the steering arm is relocated, and requires the tierod to be inverted (to the top of the arm). I'm not sure if the steering geometry was also changed or if this just keeps the tierod-end away from road debris. The camber is strongly negative at the moment (prior to alignment adjustments). This should put the center of the tire close to the projected steering-axis-line of the raised suspension, keeping the scrub radius close to stock.

The wheel-backspacing limitations have to do with the the possible interference between the wheel and the vertical tower of the knuckle. Some of the Bling Trucks like to run the super wide tires and wheels, which may rub the knuckle tower.

The spring-under-axle definitely reduces axle wrap, and transfers the traction forces to the frame/body more efficiently.

Off road race-suspension design can be another one of those 20 people and 20 opinions issues, when it comes to the desired alignment settings, and resulting geometry changes. Most of the winning designs have a zero to negative scrub radius, so a flat tire or blown caliper has less effect, while continuing to blast down the road (driving on a flat is common, and clamping off a broken brake line is also common). They typically run a little negative camber (less than 1 degree), and somewhat heavy caster (4 - 7 degrees). And they do everything possible to eliminate bump-steer, through the full cycle (up / down) of the suspension. Stadium racers use a completely different setup; more like short course pavement racing, with huge suspension travel.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-16-2010, 09:05 PM

09-16-2010, 09:05 PM

|

#8

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

I took it in for an alignment today. They were able to get the settings close to spec.; but had trouble getting the camber to come into spec, and maintain decent caster. It looks like this is mostly due to the factory suspension being so compressed, as Booster pointed out with their R/T.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-16-2010, 10:07 PM

09-16-2010, 10:07 PM

|

#9

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

It could also be that the design of the spindles intentionally puts some negative camber on them (if that is the way you are off), to help in off road handling. Getting the sag out might still be enough to get you in, though.

Just thought-In an earlier post it was mentioned by someone that I had "diesel" springs. The springs I got are aftermarket, and were originally designed to fix the diesel vans that were sitting low in the front. It appears GM probably doesn't use a bigger spring on the diesels, just lowers the load capacity. The original springs are for the GM rated 4300# max load front axle loading, where the new ones would handle 5000#. It is very likely that if you got springs out of a diesel van, they wouldn't lift you up much, if any.

|

|

|

09-17-2010, 12:08 AM

09-17-2010, 12:08 AM

|

#10

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

Good point, about the springs. Thanks for the clarification. I do remember reading about what pushed them to develop those 5000# springs.

The extra negative camber is definitely designed into the new knuckle. I think it would normally be able to obtain proper alignment numbers, except when the suspension is all the way up or all the way down. In our case - all the way up.

Springs will be next on the list. TuffTruck 5000# up front. Looking for an off the shelf application for the rear; but will probably have to spec something out, and have them custom built.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-17-2010, 12:14 AM

09-17-2010, 12:14 AM

|

#11

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

On the rear springs, you could probably just have your springs modified. Remove the overload spring and add a regular leaf, then rearch. It would probably be a lot less expensive. The biggest question would be if the existing spring is long enough to keep decent shackle angle at the increased height, especially if you go another 2" in front and need to match it.

|

|

|

09-22-2010, 08:13 PM

09-22-2010, 08:13 PM

|

#12

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

The latest info:

The CST spindle lift is made very well. It is an excellent piece of aftermarket equipment.

But, I can not recommend it for our Chevy based vans. There are a couple differences between knuckle on the 1 ton van and the 1 ton truck, that this is not a good modification.

1) The tie-rod end (TRE)on the van, enters the knuckle from the bottom. On the truck it enters from the top. Therefore the tapered hole in the lift- knuckle has the TRE coming in from the top also. This puts the tie-rod at an angle that causes bumpsteer. This is a problem when entering a corner, hitting a bump, and worse when you hit a bump in a corner.

2) The brake caliper mount is 3/16" outboard on the van. A set of spacers needs to be used, to properly mount the caliper. It works fine, I just don't like it.

3) The way CST designed the scrub radius, or SI angle, it creates excessive negative camber. There is more negative camber than than the alignment adjustments can correct. And that leaves the caster lower than desired.

Conclusion: With the squirrelly alignment and bumpsteer, it is like trying to herd the van down the road. There are things that can be done, to solve each of these problems. It just takes more time & money. I may keep this lift, and just fix the bumpsteer, for now.

As discussed earlier, the Roadtrek sits 2" lower than a stock van. So this 4" lift is only 2" above factory height. If I add another 2" with a better set of springs, it will be 4" over factory height (with a 6" lift), and ride much better. Or I could remove this spindle lift, and install the TuffTruck springs listed by Booster, along with a metal lift spacer. This can easily create the 4" lift, without the bumpsteer and alignment issues. I wish I had known about the springs last year, when I purchased this lift-kit.

I promise to post pictures to these posts, so folks can see what this all looks like.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-22-2010, 11:04 PM

09-22-2010, 11:04 PM

|

#13

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

Quote:

|

Originally Posted by Photog

The latest info:

As discussed earlier, the Roadtrek sits 2" lower than a stock van. So this 4" lift is only 2" above factory height. If I add another 2" with a better set of springs, it will be 4" over factory height (with a 6" lift), and ride much better. Or I could remove this spindle lift, and install the TuffTruck springs listed by Booster, along with a metal lift spacer. This can easily create the 4" lift, without the bumpsteer and alignment issues. I wish I had known about the springs last year, when I purchased this lift-kit.

|

That's a bummer about the spindle fit, but those problems surely will make it hard to keep on the road.

I wish I had known about the springs a year ago, too, as it would have saved the work I had to do on our valves, but it appears they didn't exist a year ago. In fact, I had a hard time getting mine, as they had never sold a set for a 6.0 gas van, only diesels, and they wanted to test them first. I think I got ours in July of this year.

If you want to go to 4" higher than it is stock, you may want to have them wind you a longer spring, instead of using the spacers under them. If I remember right, these springs are not end ground flat, so the spacers need to be machined to the shape of the spring end so they don't cause stress risers in the spring. There is also a Roadtrek owner in Oregon or Washington that had a source for custom springs, that was pretty reasonable. Since they have the specs on the ones they make, it might be easy for TuffTruck to do some higher ones.

|

|

|

09-23-2010, 12:06 AM

09-23-2010, 12:06 AM

|

#14

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

That's a great idea. I wonder how much longer the spring would need to be, to gain 2" more inches.

Edit: I just spoke with CST designer. They do flip the TRE from bottom to top, but the TRE is located in a different place on the trucks than the vans.

To say it a different way, CST moves the steering arm down, and reverse the TRE to mount from the top. This keeps the steering geometry the same; but that is for the 2500HD/3500 truck. It would seem the the steering arm on the van and truck (factory positions) are different.

Bummer.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

09-23-2010, 12:47 AM

09-23-2010, 12:47 AM

|

#15

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

Quote:

|

Originally Posted by Photog

That's a great idea. I wonder how much longer the spring would need to be, to gain 2" more inches.

|

They know the design of their current spring (mine), and you can let them know that I went up 2", with a 6.0. They also know that a diesel went up 1", IIRC. I would think that would be enough information to let them load it into their spring designer program and come up with something for you.

|

|

|

10-06-2010, 09:01 PM

10-06-2010, 09:01 PM

|

#16

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

We have just returned from a 2600 mile trip. Our first trip longer than a weekend. We had a great time. It is wonderful to travel in the Class B rig.

We drove from Gig Harbor, Washington, to Richfield, Utah. We stopped in at Advanced 4WD in Salt Lake City, to discuss adding 4X4 in a couple years. While we were there, I had them install a rear sway bar. It can not be installed in a normal fashion, due to the Onan generator exhaust routing. The guys at Advanced 4WD did a great job. And the sway bar improved the road manners (different since the lift).

There is a major amount of bump steer. It will be corrected this month, but it made for some stressful driving. I will post photos of the problem and the fix.

With the lift, I was not worried about where I went. Never bumped the bottom. Here are a few pics of the lifted RT. A couple camping spots, and a couple en-route shots.

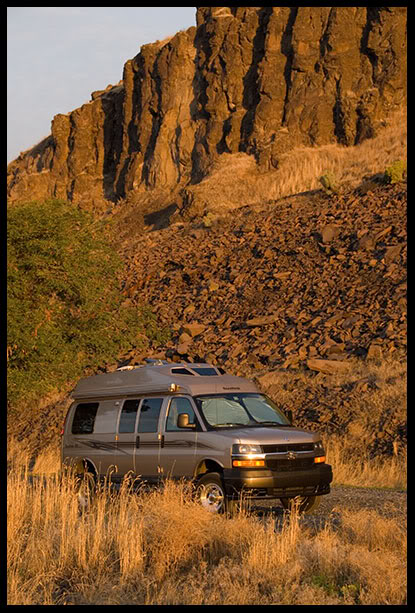

1st camp, along the Columbia River, near Mary Hill.

You can easily see under the van, in this shot. We checked out a series of camping spots, south of Twin Falls, ID. Most of them would not be accessible without the lift.

Here we are, in Capitol Reef NP

A roadside camp at Pequop pass on I-80, in Nevada.

Here is a spot off the Spring Creek Road in Oregon, off of I-84. I could not get to this spot, without the lift. There is a short climb from the dirt road, to this parking spot. The ground was very uneven, due to deep ruts made when the ground was soggy. Nice sunrise colors, over the trees. Looks like a forest fire.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

10-06-2010, 09:24 PM

10-06-2010, 09:24 PM

|

#17

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,005

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

How did they do the rear bar? I have been looking to put one in, but the Hellwig would interfere with the genny, unless you move the generator back.

Also, would the bar they put in interfere with the Firestone air bags that go in front of the axle?

I have been looking at building my own out of 1.375 hex, 4150 stock, but the 90* joints get tough to make tight enough to handle the two way motion a bar sees (torsion bars only see one way).

|

|

|

10-06-2010, 11:30 PM

10-06-2010, 11:30 PM

|

#18

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

The Antirock ( http://www.currieenterprises.com/cestore/antirock.aspx ) sway bar might be easier to install.

I'm not sure which sway bar they installed, but I believe it is a Chevy factory part. They welded mounts to the frame and axle, and the bar is mounted under the axle. I will try to get a photo of the installation, and post it here.

At some point, I plan to get an Onan resonator (muffler), and have a muffler shop install it, with a re-routing of the pipe. Roadtrek routs the generator exhaust pipe between the Gen and the rear axle. On my RT, the differential housing rubs the Gen pipe.

If I can have the Gen pipe routed to come out on the same side as the van's tailpipe, it may open up space for a better sway bar installation.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

10-07-2010, 09:04 PM

10-07-2010, 09:04 PM

|

#19

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

Here are some pics of the sway bar mounting position. It looks a little low.

In this photo, you can almost see the contact point, between the Onan exhaust and the differential cover.

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

10-10-2010, 06:46 PM

10-10-2010, 06:46 PM

|

#20

|

|

Platinum Member

Join Date: Mar 2008

Location: Gig Harbor, WA

Posts: 372

|

Re: Photog's Lifted 2009 Roadtrek 190V

Re: Photog's Lifted 2009 Roadtrek 190V

Booster,

Have you ever measured the amount of remaining droop (down travel), left in your suspension, since the lift?

Basically measuring from a place on the wheel to the fender, then jack under the frame until the tire lifts off the ground, and measure again. The difference in the two numbers is the amount of droop from ride height.

I did some measuring on Saturday, and I get 3" of droop, before the upper ball joint reaches its limits.

Based on some of the design differences between the factory knuckle and my 4" lift knuckle, I think the factory knuckle would allow more than 4" of droop from standard ride height of the RT RV. On your RT, you have used up 2" of that droop, with the new spring lift. I believe this puts your suspension back to stock ride height (if I read the other forum correctly). I am wondering how much droop you have left, with the factory suspension components. I think there should be more than 2" left.

If there is only a total of 4" of droop, from RT ride height, then a typical spring-and-spacer lift of 4" would use up all the droop in our suspension system.

Any thoughts or measurements?

__________________

Brian

2009 Roadtrek 190V, 5" lift - Build Thread

2004 Toyota 4Runner

2014 Honda CR-V

1965 Dodge Coronet 440

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|